CNC Turning Centers

Delivering outstanding productivity and performance

Mazak offers world-class CNC turning centres that combine advanced technology, productivity, and value. A wide variety of machine specifications - from 2-axis models to turning centres with rotary tool spindle, Y-axis and second spindle - are available to meet your production requirements.

QUICK TURN PRIMOS series, a compact & high-performance CNC turning centre equipped with integral spindle motor providing unsurpassed productivity with minimum floor space requirements.

QT COMPACT series, entry-level models boasting Mazak’s integrated spindle technology for the main spindle and Tool Eye as standard, together offer both improved performance and accuracy. An extensive range offering a compact and cost-effective solution for turning, milling, Y-axis, and second spindle capability.

QUICK TURN series, high performance turning centres that make complex parts accurately and with reduced set up time. Equipped with the new Smooth Mill Drive turret with BMT or VDI tooling interface and 5000 or 10000rpm capability.

New MULTIPLEX W series is ideally suited to high-volume applications and features a slant bed for improved chip management. The machine employs two Smooth Mill Drive turrets to perform continuous and simultaneous machining.

HQR series, 2 turret, 2 spindle machines offering optimised cycle times for higher volume parts, by enabling tandem turning or milling by means of the upper and lower turrets working concurrently. Y-axis functionality on both the upper and lower turrets also increases the flexibility for more complex components.

High Productivity Machining Performance

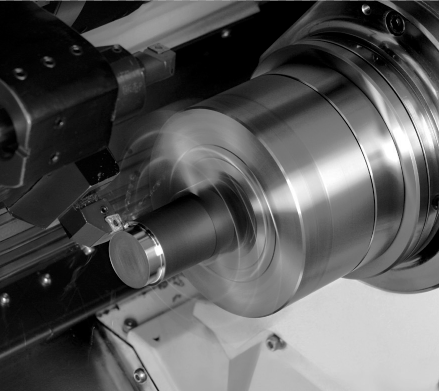

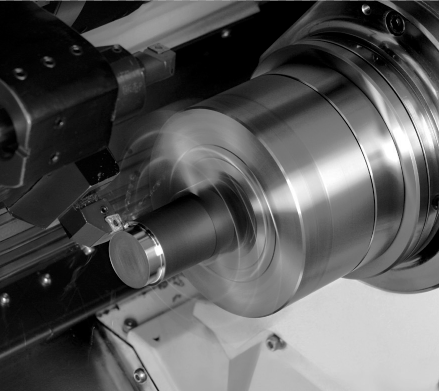

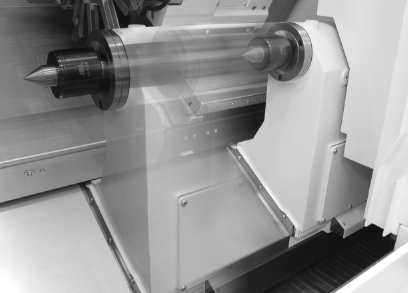

Integral spindle motor ensures high productivity and high accuracy

Vibration is minimised during high-speed operation to ensure exceptional surface finishes and maximum tool life.

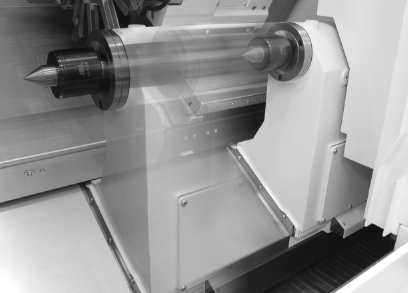

Featuring NC tailstock for fully automatic operation and ease of setup

The tailstock travel and thrust is controlled by a servo motor. The low thrust ensures high accuracy turning even for small diameter shaft workpiece.

Smooth Mill Drive for high torque capability

Standard 5000rpm and optional high speed 10000 rpm Smooth Mill Drive with BMT or VDI turret meet the requirements of wide variety of materials.

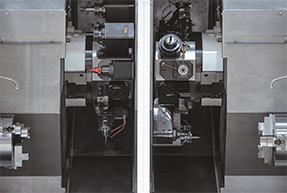

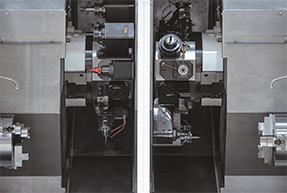

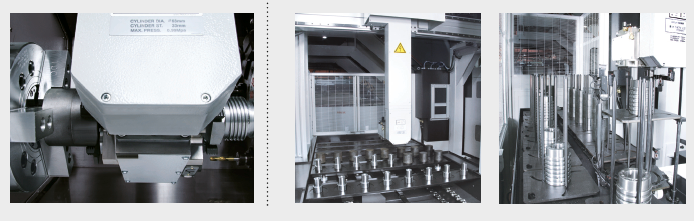

2 turret/ 2 spindle machine design for reduced cycle time

2 turret/ 2 spindle machine design for reduced cycle time

HQR series machines perform high efficiency cutting such as simultaneous 1st and 2nd operations & balanced cutting by utilizing the upper and lower turrets.

Factory Automation

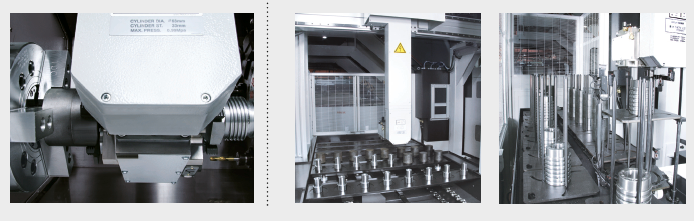

Gantry loader system

The gantry loader system for workpiece loading / unloading realises unmanned operation over extended periods of time.

Bar Feeder and workpiece unloader

Effective operation from bar material to finished workpiece

MAZATROL SmoothG

- PC with W

indows 8® embedded OS

indows 8® embedded OS

- Touch screen operation - Operates similar to your smart phone/tablet

- Fastest CNC in the world -Latest hardware and software for unprecedented speed and precision

- MAZATROL Smooth graphical user interface for unsurpassed ease of operation

- High precision machining of complex contours at high speed feedrates

MAZATROL SmoothC

- Fastest CNC in the world - latest hardware and software for unprecedented speed and precision

- Compact operation panel with keypad

- Essential functions for increased ease of programming

Ergonomics

Large window

Large window is located on the operator door for convenient monitoring of machine operation.

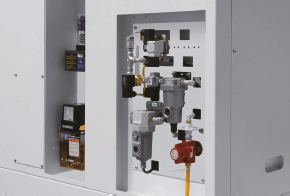

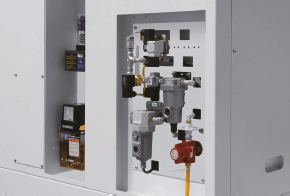

Ease of maintenance

All the items that require frequent access, such as hydraulic and pneumatic valves and lubrication inlets, are at one central location for convenient daily maintenance.

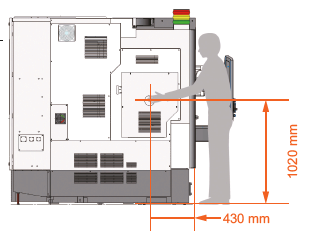

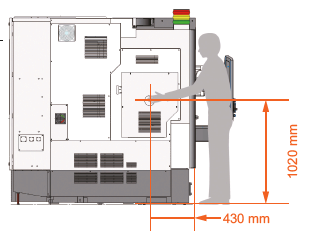

Convenient setup

The distance from the front cover to the spindle centre line is small for convenient setup and workpiece loading /unloading.

2 turret/ 2 spindle machine design for reduced cycle time

2 turret/ 2 spindle machine design for reduced cycle time

indows 8® embedded OS

indows 8® embedded OS