OPTIPLEX 3015 NEO

Precision 2D Fiber Laser cutting machine

The OPTIPLEX 3015 NEO is a 2D fiber laser cutting machine available in a wide range of powers, from 3 kW to 20 kW, and different configuration, with Beam Diameter Control or with Beam Diameter Control and Beam Shaping Technology. Mazak’s advanced Beam Shaping technology, complemented by Beam Diameter Control, delivers asuperior cutting qualityfor sheet metal processing.

The proprietary Mazak Multi-Control Torch 3 cutting head enables Intelligent Functions that drastically reduces setting and cutting time by automatically change setting of the machine. The new MAZATROL SmoothLxCNC control system features a double 21,5-inc touch display and new GraphicalUser Interface and the Human Machine Interface ensuring fast operation.

Operator access to the cutting area is enhanced by front and side access doors that open the full width and length of the machine.

Key features:

- Unique combination of Beam Shaping Technology and Beam Diameter Control ensures the best cutting performance on various materials and thicknesses

- Front and side doors for easy accessibility

- Mazak proprietary Multi-Control Torch 3 and Intelligent Functions allow high-quality and high-speed cutting

- New MAZATROL SmoothLxCNC control provides fast operation

- Available from 3kW to 20 Kw Fiber laser resonator configuration

- Max. workpiece size: 1525mm x 3050mm

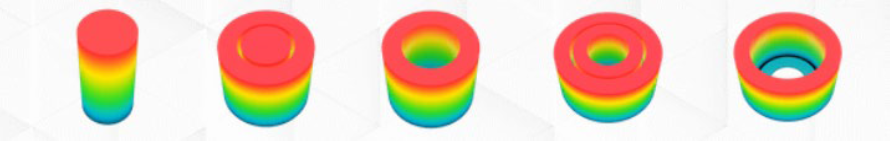

The state-of-the-art beam shaping technology:

Beam Shaping Technology enables to change the power distribution of the laser beam on the workpiece in a controllable and repeatable manner to achieve the best processing results.

Thanks to this technology, the operator can switch from a small flat-top to a large donut with all the shapes in between.

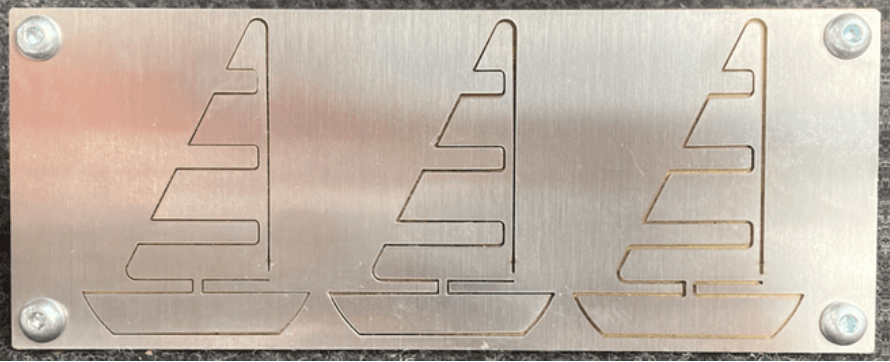

On the left is a workpiece cut with standard technology. In the middle and on the right a cut with BST in 2 different modes, resulting in 2 different kerf widths.

On the left is a workpiece cut with standard technology. In the middle and on the right a cut with BST in 2 different modes, resulting in 2 different kerf widths.

Maskine specifikationer

| 15.0 kW Laser | Værdi | |

|---|---|---|

| Machine Specifications | Axis processing movement | Flying optics |

| Maximum work piece size X-Y | 1525mm x 3050 mm | |

| Work table height | 900 mm | |

| Axis travel X-Y | 1595mm x 3110 mm | |

| Z axis travel | 135 mm | |

| Rapid traverse rate X-Y | 120 m/min | |

| Rapid traverse rate Z | 60 m/min | |

| Axis drive system X1/X2 - Y | Rack and pinion | |

| Axis drive system Z | Ball screw | |

| Positional accuracy X-Y | +/-0.05/500mm | |

| Positional accuracy Z | +/-0.01/100mm | |

| Cutting head | Mazak multi-control torch 3.0 | |

| Z axis profiler | Non contact type | |

| Lighting system | LED light | |

| Operation status indicator lights | Yellow/laser source on, red/laser beam on | |

| Programmable assist gas ports | 3 types(Oxygen,air,and assist gas) | |

| Noise level laser | Maximum 80 dBA | |

| Safety interlock system | Door, shuttle door, hood | |

| Machine base | Precision machined single cast iron base | |

| System weight | 14800kg | |

| Laser Generator Specifications | Generator style | Fiber laser |

| Power stability | +/- 1.0% | |

| Laser wave length | 1,080.00 Nm | |

| Laser power mode selection | CW, pulsed | |

| Circuit cooled | Torch, laser | |

| Name | MAZATROL SmoothLx | |

| Data input | Touch panel | |

| Monitor | 21.5" wide full monitor | |

| Graphic preview display | 2D tool path | |

| Memory storage | 64 GB | |

| Program storage | 1 GB | |

| Input ports | USB 2.0 * 2ports | |

| Network connection | LAN 1 Port ( 100/1000 BASE) | |

| Minimum input command | 0.001 mm | |

| Servo System | Digital | |

| Position system | Encoder | |

| Control method | Semi-closed loop | |

| Maximum work piece weight per pallet | 1,500 kg | |

| Maximum loading height of work piece | Upper pallet 50mm, Lower pallet 40mm | |

| Maximum work piece size X-Y | 1525mm - 3050mm | |

| Work piece reference | 2 reference stops or laser edge find | |

| Clamps | 2 | |

| Number pallets | 2 | |

| Camber | 3 mm | |

| Angle | 6 mm | |

| Flatness | 2 mm | |