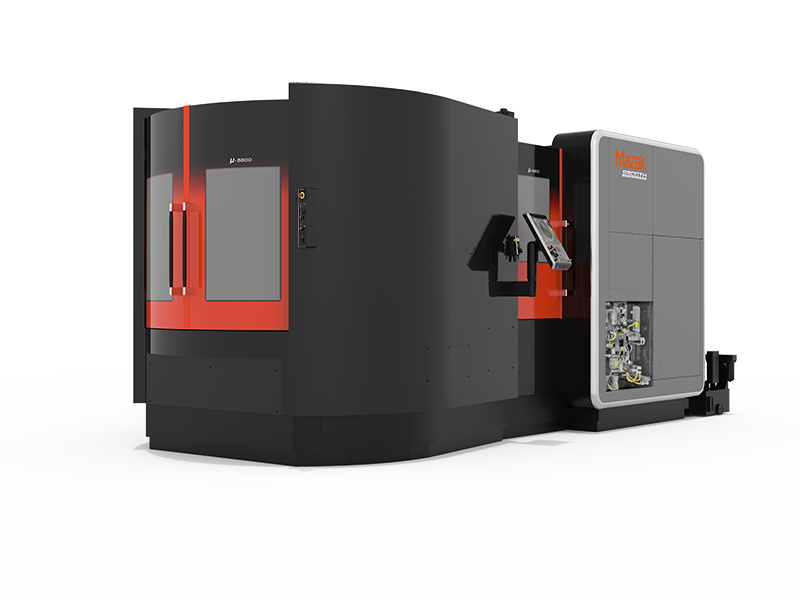

µ-8800

The µ-8800 is a high-performance small machining center for 800×800 mm pallets. It is equipped with a variety of countermeasures for heat displacement to ensure stable accuracy over long periods of operation, providing the same machining accuracy as a Jig-borer.

µ Series

High Speed, high accuracy Horizontal Machining Centers

Machine construction and countermeasures for heat displacement to ensure high continuous machining accuracy. Temperature controlled traverse axes and high rigidity indexing table provides stable high accuracy machining.

µ series high torque, high speed spindle for high efficiency machining.

Maskine specifikationer

| Standard Machine | Værdi | |

|---|---|---|

| CAPACITY | Maximum workpiece diameter | 1,450 mm |

| Maximum workpiece height | 1,450 mm | |

| X-axis travel (column right and left) | 1,400 mm | |

| Y-axis travel (spindle up and down) | 1,200 mm | |

| Z-axis travel (table back and forth) | 1,325 mm | |

| SPINDLE (standard) | Spindle taper hole | 7/24 taper: No.50 BIG PLUS |

| Spindle speed maximum | 4,000 min-¹ | |

| TABLE & PALLET | Pallet width | 800 mm |

| Pallet length | 800 mm | |

| ATC TOOL MAGAZINE | No. of tool pockets (standard) | 60 |

| Tool shank | MAS BT-50/ BBT-50/ CAT-50/ HSK-A-100 | |

| MACHINE SIZE | Width | 3,881 mm |

| Length | 8,186 mm | |