MULTI PALLET POOL (MPP)

Automatic operation system for small volume production

The MPP (MULTI PALLET POOL) is a new system to meet the increasing worldwide demand for automation. It is designed to provide high productivity for high-mix, low batch production.

3 key benefits

- Compact floor space for multiple pallet stocker

- Possible to expand the initial MPP installation to meet increasing production requirements

- The MPP utilizes the same software as the Mazak FMS system, which is highly regarded worldwide for its ease of operation and high productivity’

MPP can best be used when

- Automation is required on a limited scale

- Limited floor space prevents a system with a horizontal pallet stocker from being installed

- The MPP is possible as a ‘retrofit’ to an existing machine

See how the MPP Can benefit the

VARIAXIS i-600, i-700 & i-700 T

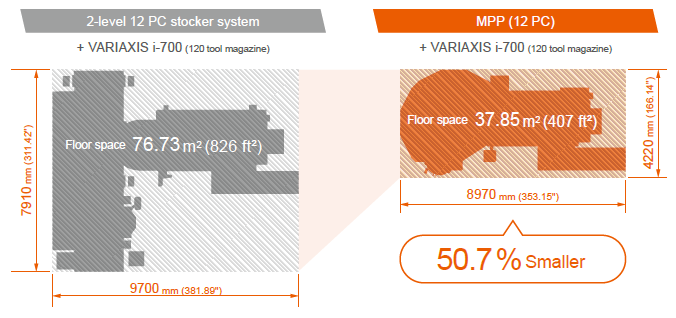

Compact floor space compact

When compared to systems with horizontal pallet stockers, the same amount of pallets can be stored in smaller floor space.

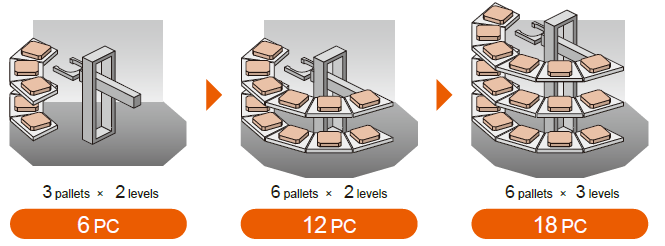

Flexible pallet stocker capacity

6, 12 and 18 pallet storage capacities are available.

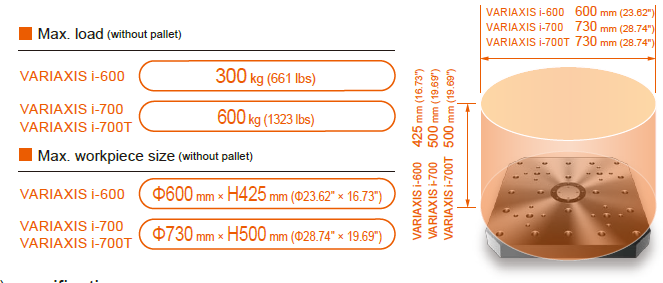

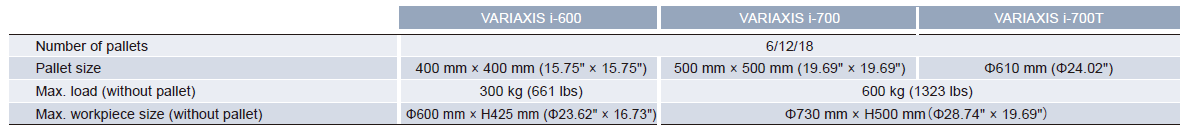

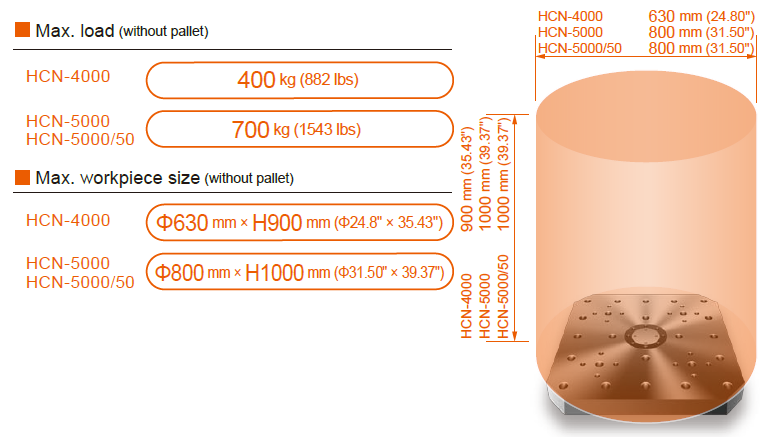

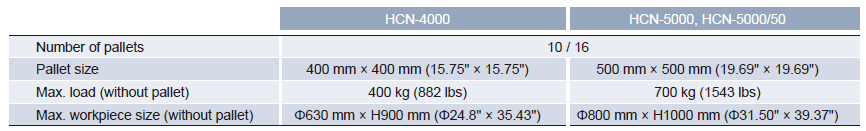

Workpiece specifications

MPP Specifications

HCN-4000, 5000, 5000/50

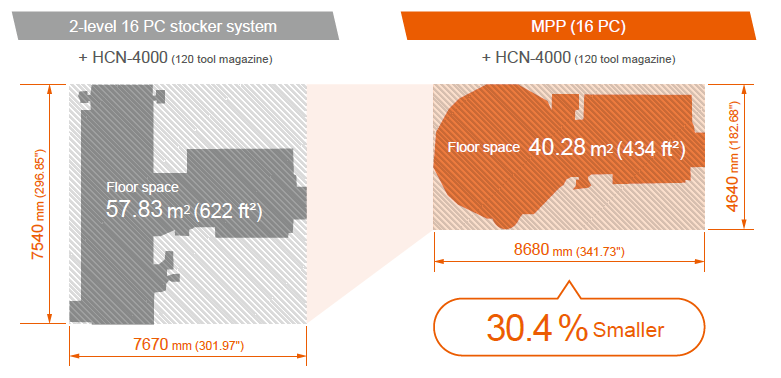

Compact floor space requirement

When compared to systems with horizontal pallet stockers, the same amount of pallets can be stored in smaller floor space.

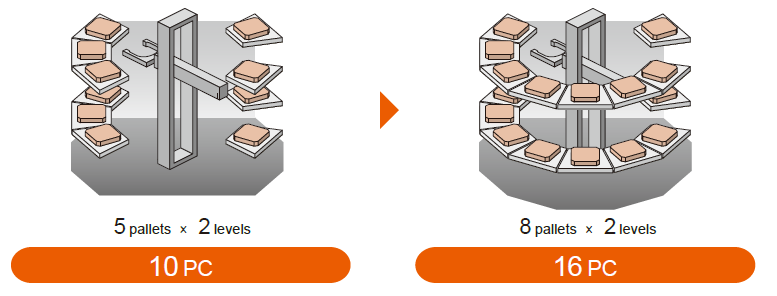

Flexible pallet stocker capacity

10 and 16 pallet storage capacities are available.