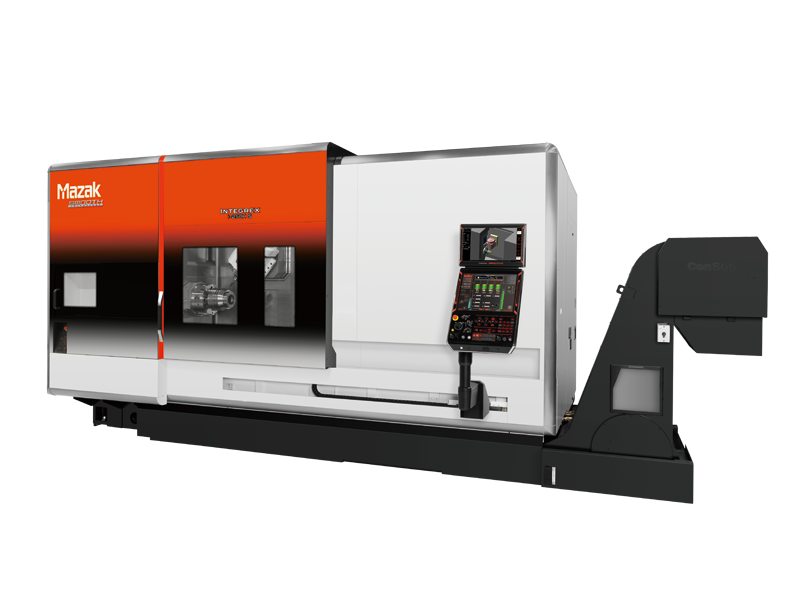

INTEGREX i-350H ST

Multi-tasking Mill-Turn 5-axis machine

INTEGREX i-350H ST

The latest generation INTEGREX i-350H ST combines turning and B-axis milling operations within a compact single machine tool.

- Specifically designed for integration with automation systems including; Bar Feeders, TA (Workpiece loading / unloading Robot) and automatic jaw changers.

- Variety of milling spindle specifications available

- Fitted with a newly designed 12 station driven tool lower turret

- 38 Tool magazine can be loaded from front and rear (optional: 74, 112, 157, 277 tools)

- Next generation MAZATROL SmoothAI CNC control

Maskine specifikationer

| 1500 mm Bed (Universal) | Værdi | |

|---|---|---|

| CAPACITY | Chuck size main spindle | 10 " |

| Chuck size secondary spindle | 10 " | |

| Maximum machining diameter (upper turret) | 670 mm | |

| Maximum machining diameter (lower turret) | 420 mm | |

| Bar work capability main spindle (dependent on chuck system) | 80 mm | |

| Bar work capability secondary spindle | 80 mm | |

| MAIN SPINDLE | Rotating speed maximum | 4,000 min-¹ |

| Motor output (40% ED rating) | 30.0 kW | |

| SECONDARY SPINDLE | Rotating speed maximum | 4,000 min-¹ |

| Motor output (40% ED rating) | 26.0 kW | |

| MILLING HEAD | Milling spindle speed maximum | 12,000 min-¹ |

| LOWER TURRET | Number of tools mounted | 12 |

| FEED AXES | Movement stroke X | 695 mm |

| Movement stroke Z | 1,585 mm | |

| Movement stroke Y | 300 mm | |

| Movement stroke B | 240° (-30° ~ +210°) | |

| Movement stroke X2 | 220 mm | |

| Movement stroke Z2 | 1,539 mm | |

| Movement stroke W | 1,539 mm | |

| AUTO TOOL CHANGER & MAGAZINE | Tool storage per magazine | 38 |